P: +6017-450 7187

E: cw.lim@la-feeder.com

LA Feeding bowl tops and drive units are engineered to work seamlessly together, handling components across a wide range of industries.

Our systems are capable of feeding parts in various shapes, sizes, and materials—ensuring versatility for different application needs.

LA Feeding’s proprietary multi-magnet drive units are designed to deliver smooth and stable feeding performance, minimizing vibration impact on downstream assembly equipment.

All our drive units and control boxes are CE marked, with UL/CSA approvals available upon request for the North American market.

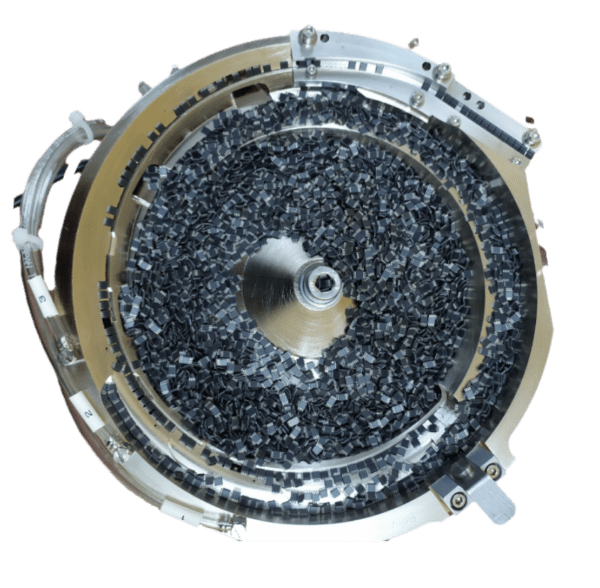

Our bowl feeders are available in various materials such as stainless steel, aluminium, and polyamide, with a selection of surface coatings—including polyurethane, Habasit, brush, flock, and Metaline—carefully chosen based on the component characteristics and application environment.

We offer bowl sizes ranging from 69mm to 1200mm in diameter, covering a comprehensive range of vibratory bowl feeders.

Standard components such as drive units, bowls, bowl centers, control boxes, and accessories (stands, base plates, sound enclosures, and sensors) are readily available. Custom requirements can also be accommodated upon request.

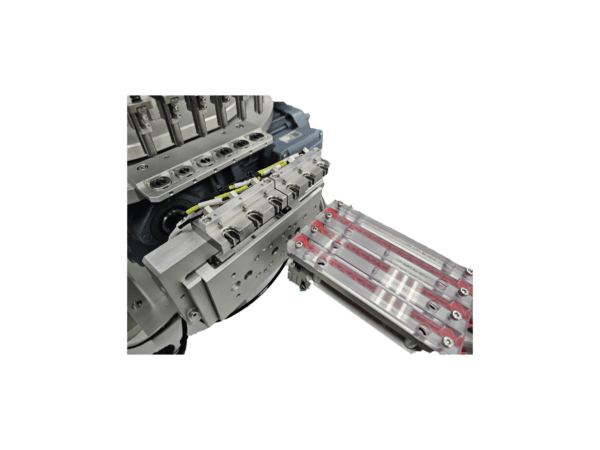

At LA Feeding, we also design and manufacture specialized tooling for part orientation.

Together with our standard modules, this enables us to deliver a fully integrated system ready for direct incorporation into your production lines, including packaging and automated assembly processes

Our Stainless steel bowl feeder is made up by mainly stainless steel grade 304 & 316.This type of bowl is mainly using hand work process to bend and roll for completing the bowl module.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

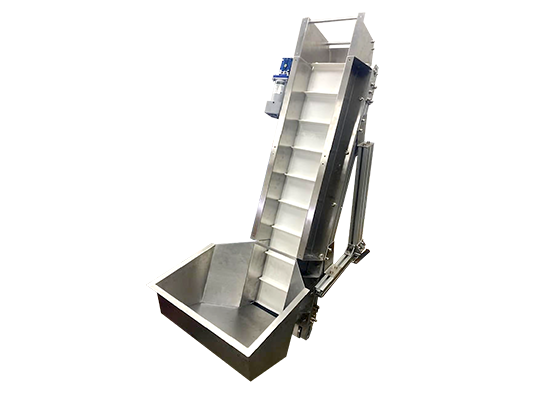

This product main function is for part storage and filling automatically into feeder bowl when it is empty. The detection is control fully by sensor. The built up parts is one set of motor drive, belting and one SUS304 hopper tank

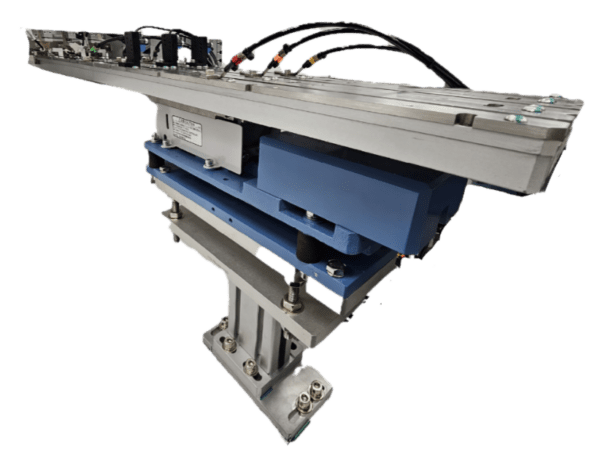

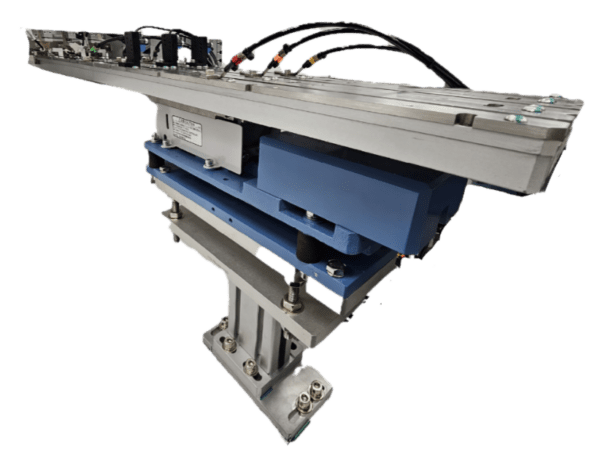

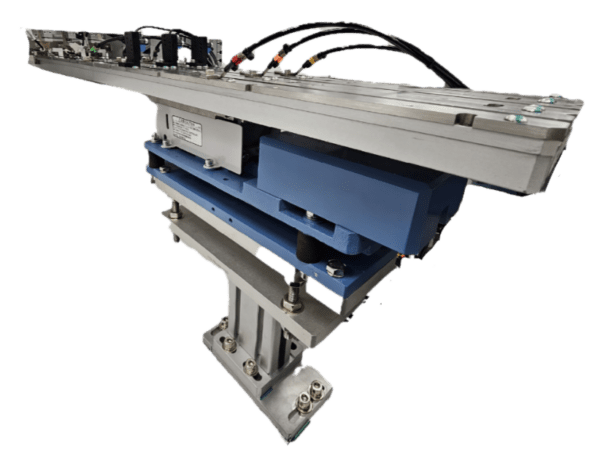

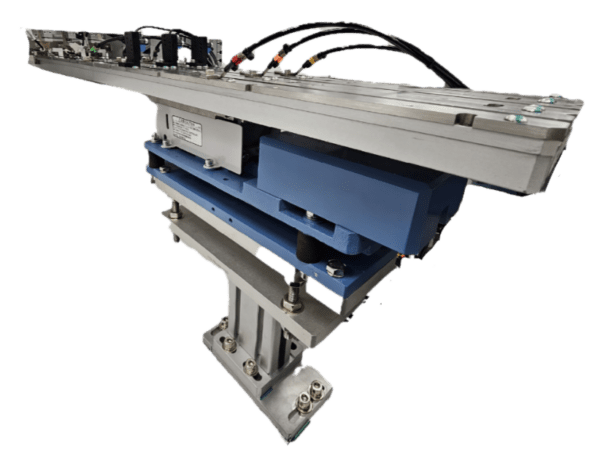

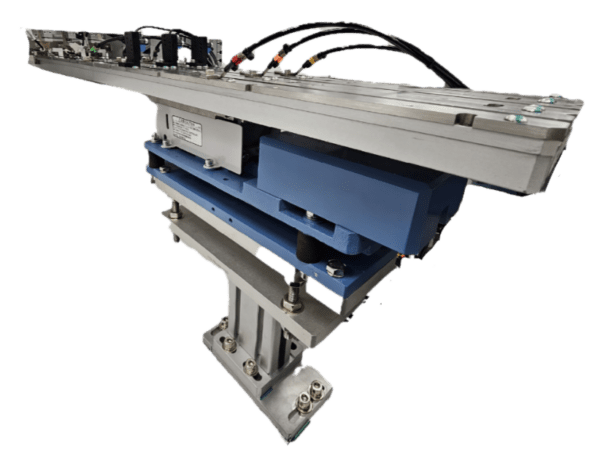

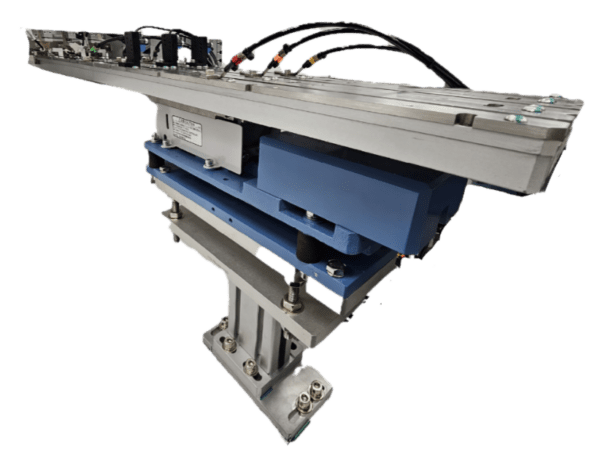

The escarpment unit function is for singulate the feeding part in just one way for easy end user for going to other process such as pick & placed, transfer for vision checking or packing process.

This type of bowl is built up by ALU 6061 material. The products are building by CNC 5 axis machining which machining from ALU rod material until finish goods.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

The polyurethane coating is a layer of rubber coating which spray inside SUS vibrator feeder bowl. The main colour for the Polyurethane coating is Blue or green colour.