P: +6017-450 7187

E: cw.lim@la-feeder.com

At LA Feeding, we specialize in the development and integration of vibratory feeding solutions that ensure smooth, reliable, and efficient part orientation and delivery for automated assembly systems. From bowl feeders to linear tracks and precision controllers, our systems are built to deliver consistency, durability, and ease of integration.

Our vibratory bowl feeder units are engineered to orient, sort, and feed a wide range of components—from simple plastic parts to intricate metal components used in industries such as medical, automotive, consumer goods, and electronics.

Each feeder is tailored to your part geometry, feeding rate, and downstream automation requirements—ensuring stable and accurate output for continuous production.

Our vibratory controller units provide precise control over the feeding system’s amplitude, frequency, and stability. Designed for plug-and-play integration, these units are essential for maintaining feeding consistency, especially in high-speed and high-sensitivity applications.

These controllers are crucial for optimizing system performance, reducing part jamming, and minimizing wear on mechanical components.

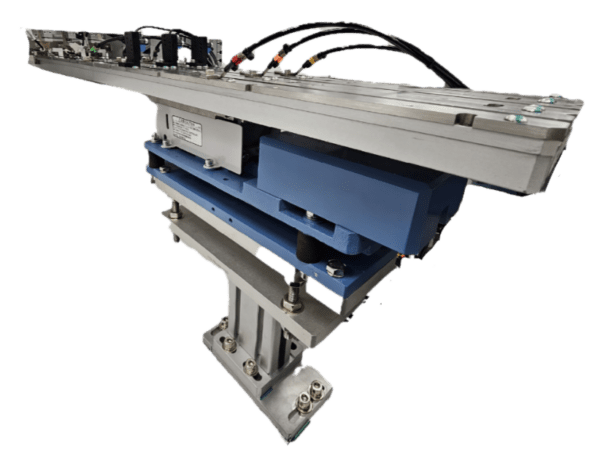

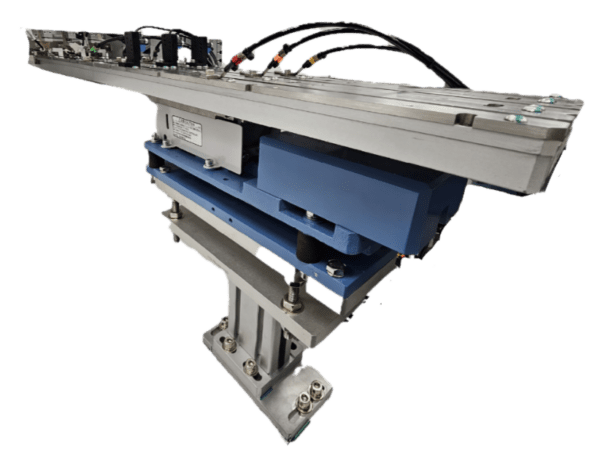

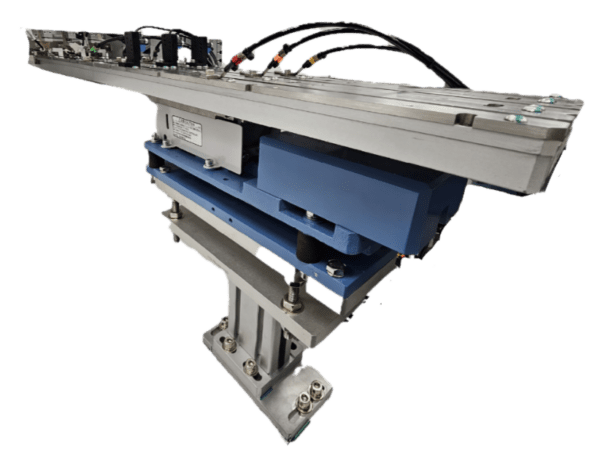

Vibratory linear feeders are used to transfer oriented parts from the bowl feeder to the next processing station in a controlled and consistent manner. LA Feeding provides robust linear feeders designed to match specific part weights, lengths, and production speeds.

Our linear feeder systems ensure seamless part handoff, maintaining alignment and spacing critical for robotic pick-up, vision inspection, or secondary processes.

With LA Feeding’s vibratory feeder and controller units, you get a fully integrated, dependable feeding system designed to streamline your production line, reduce downtime, and boost productivity.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.

Vibrator is the driver that moves the part in feeder bowl. There’s two type of vibrator which is Piezo and coil type. Both type of vibrator have its advantages.